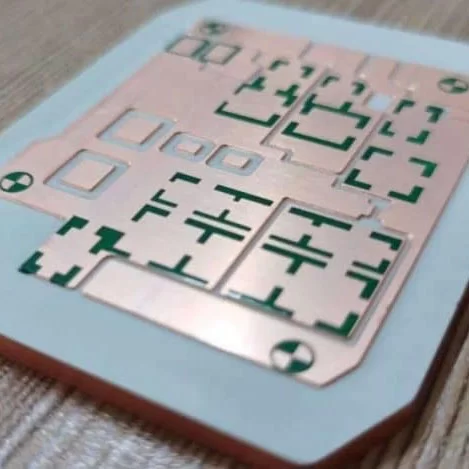

A peelable solder mask is a temporary protective coating applied to specific areas of a PCB during the manufacturing process.

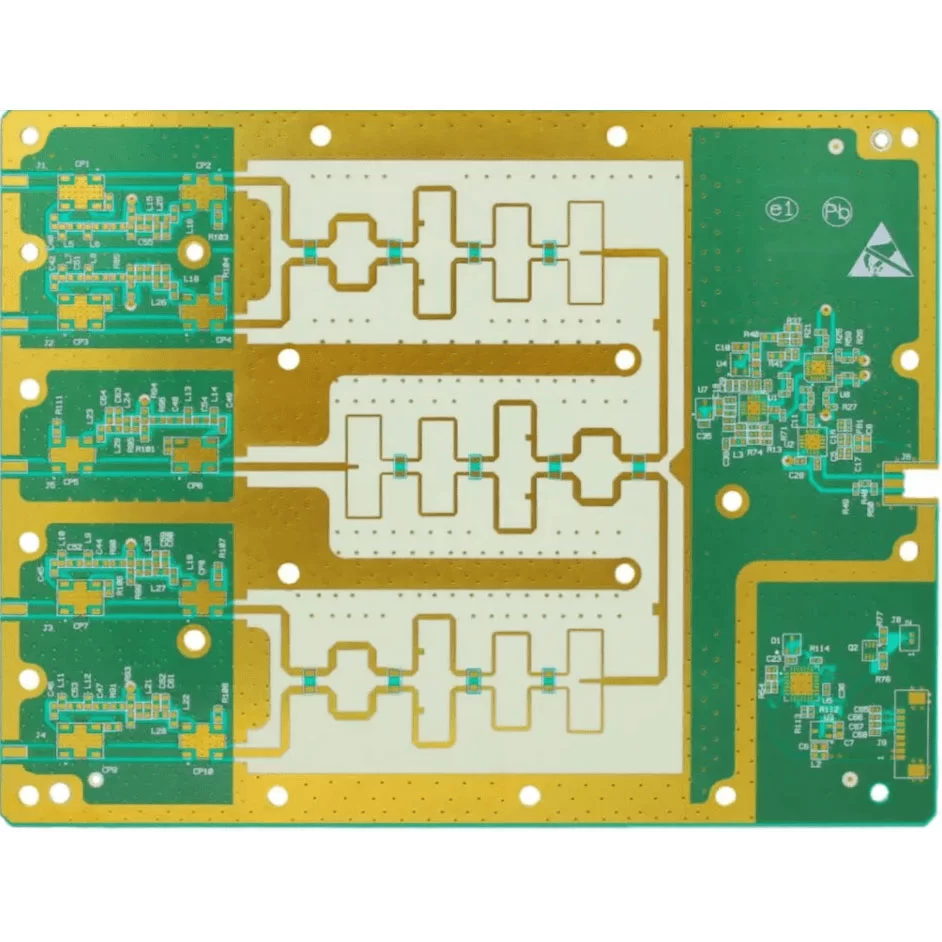

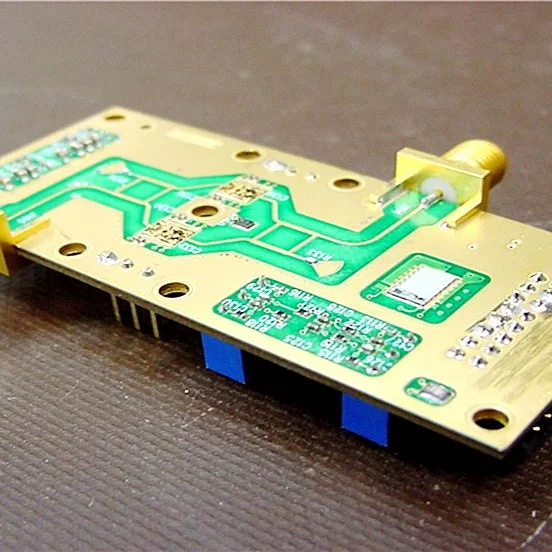

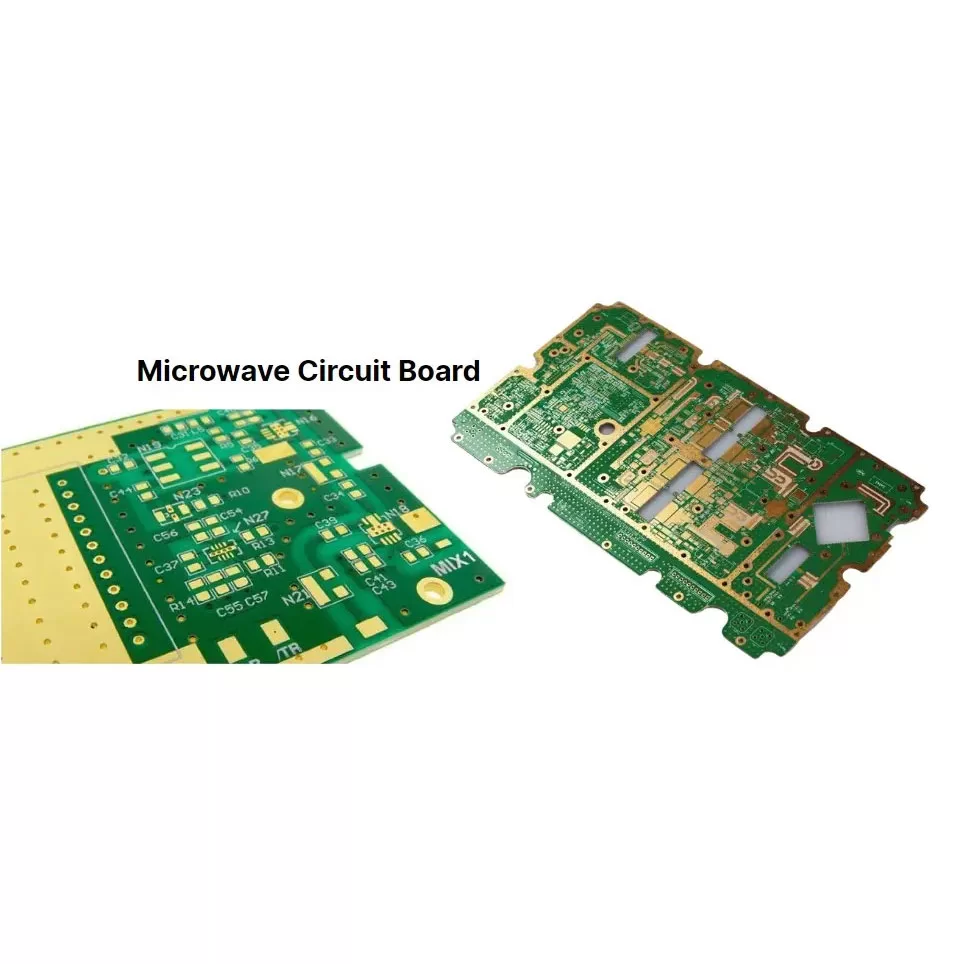

Hybrid microwave PCB is using a dissimilar materials with the intent of optimizing electrical performance and improving system reliability focused towards high-frequency RF applications.

RF PCBs are circuit boards specifically designed to handle high-frequency and radio frequency signals.

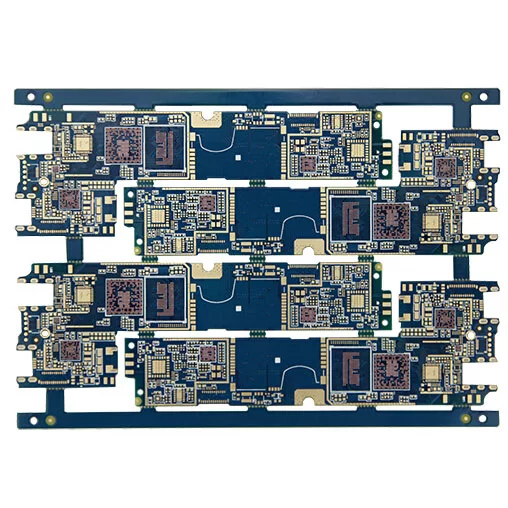

We can reduce the multilayer PCB board size with the help of inner layers as per PCB design rules.

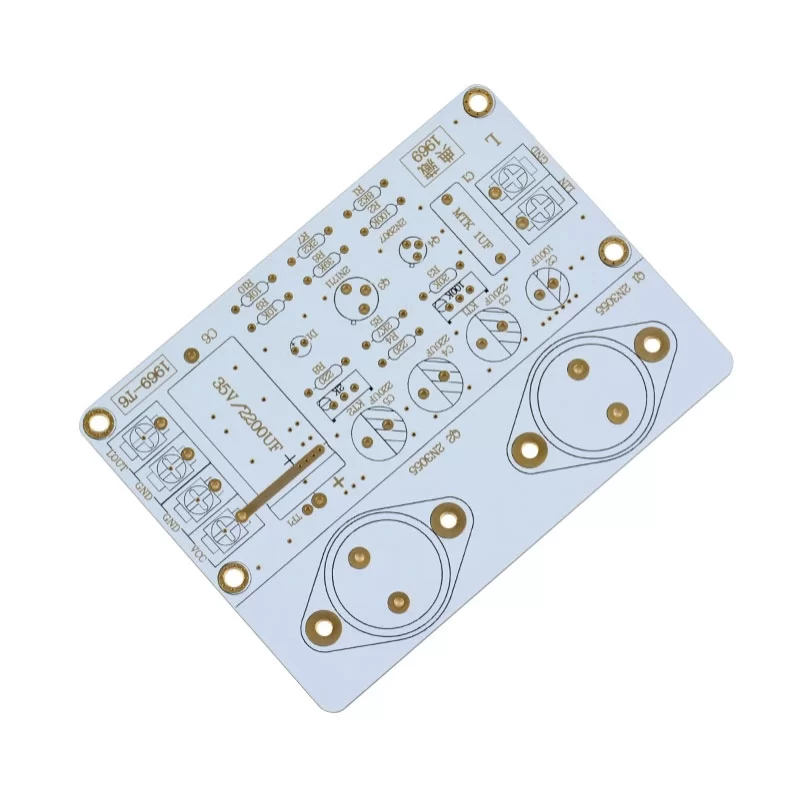

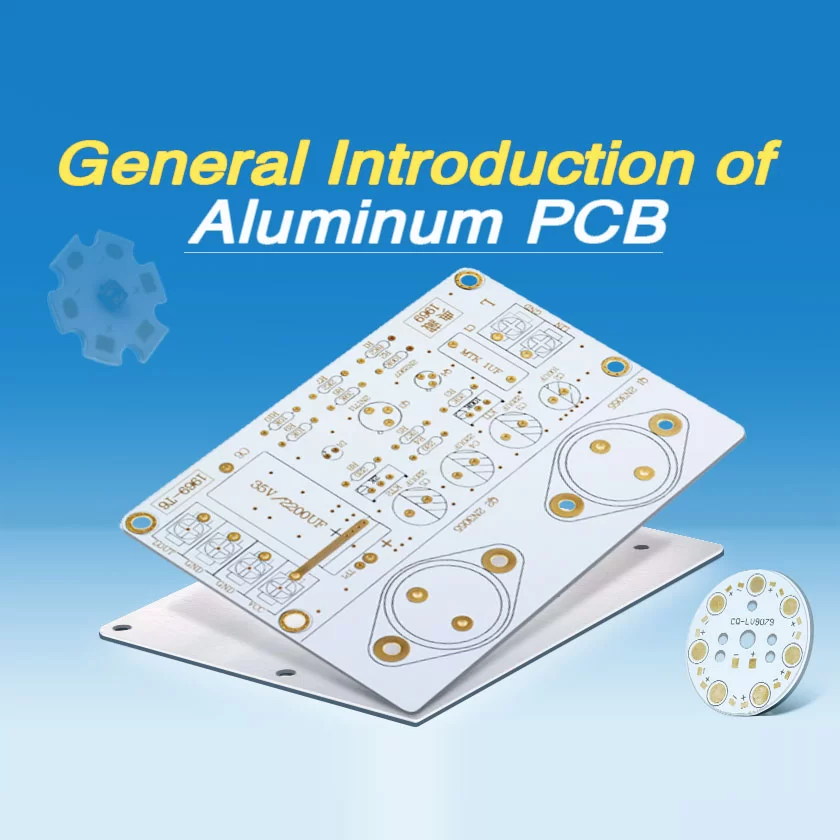

MCPCBs, also known as insulated metal substrate (IMS) PCBs or thermal clad PCBs.

Double-sided aluminum substrates are widely used in electronics manufacturing.

This PCB consists of a single layer of aluminum substrate PCB, they are comparatively simple in design and used in applications where heat management is the main concern.

Aluminum PCB, also known as metal core PCB or aluminum core PCB, is a circuit board with aluminum substrate.

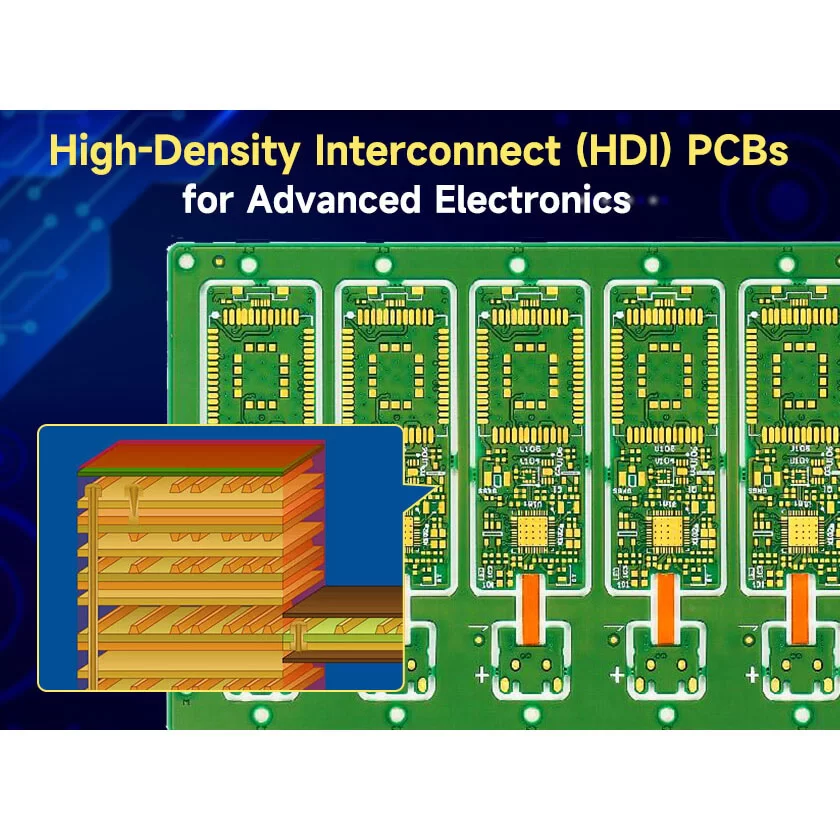

Model :6L(1+N+1)

Material:FR-4 ITEQ IT180A

Layer : 6L1+N+1 HDI

Model:10 L(1+8+1)

Layers:10

Material: SY

Finished Thickness:1.2mm

Copper Thickness:0.5OZ

Higher Functionality: Rigid PCB boards allow multiple-layer construction and connection density, it has higher functionality and flexibility in board design.

WiFi module, also called a serial port Wi-Fi module, falls under the IoT transmission layer.

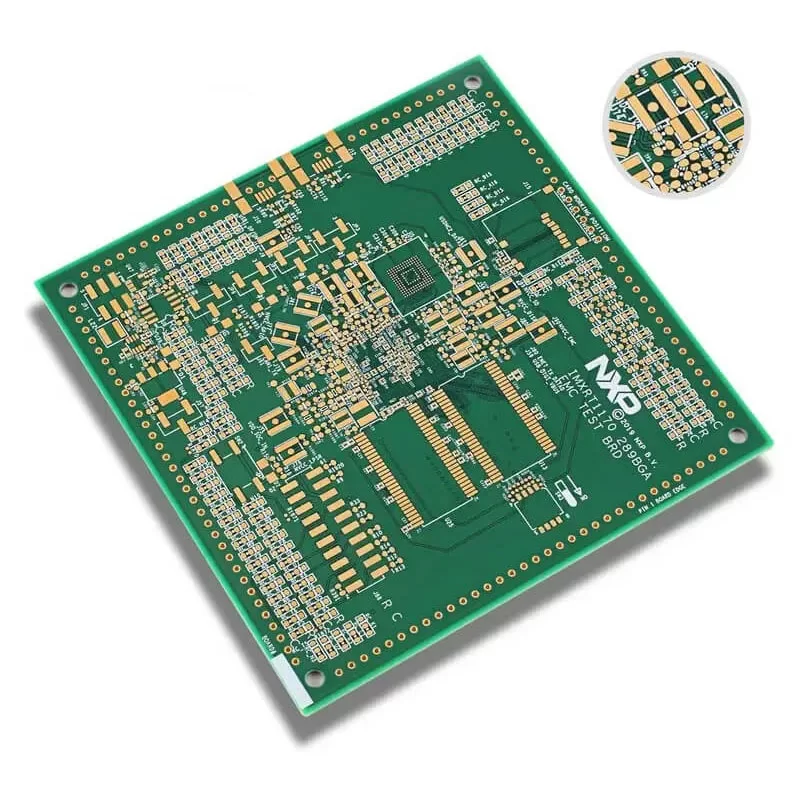

The layer count is determined by signal density and complexity. Typically, 8–12 layers are used, with cores and outer layers connected via blind and buried vias.